Thanks to the hard work of two Drexel University professors from Cherry Hill who sought something constructive to accomplish during the early days of the COVID lockdown, first responders and other health-care providers across the region have been given 35,000 face shields to protect against the virus.

Ellen Bass, a township native who moved back to the area eight years ago, and Amy Throckmorton, a Virginia transplant who relocated to Cherry Hill around the same time, serve as point persons for mass production and donations of AJFlex Face Shields.

The shields were crafted to address the severe lack of personal protective equipment health care workers faced in the first months of the pandemic.

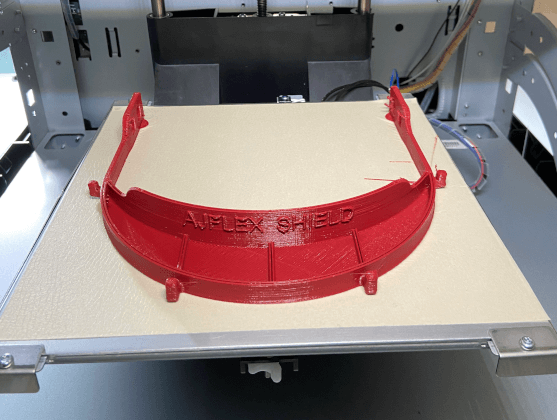

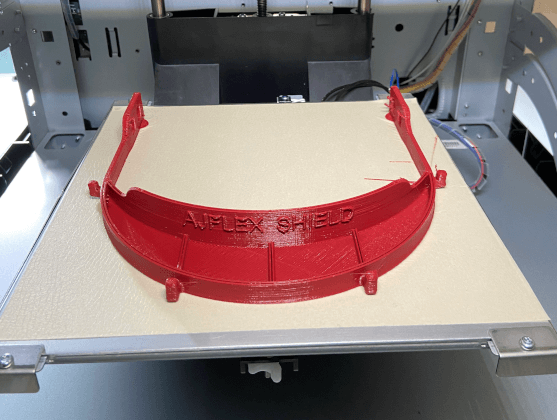

A multidisciplinary effort among Drexel’s College of Engineering, College of Computing and Informatics, Westphal College of Media Arts and Design, the university’s machine shop, Bass’ own College of Nursing and Health Professions and Throckmorton’s School of Biomedical Engineering, the shields contain basic technology that allow the wearer to adjust its headband for maximum comfort and coverage.

To date, the collaboration has created and donated more than 50,000 shields, with no plans to quit any time soon.

Among the local organizations that have benefitted from the undertaking are: Woodcrest Elementary, Barclays Health Services, Lions Gate Adult Living Facility and Right at Home. Almost 6,000 shields have been earmarked for delivery in New Jersey alone, according to Throckmorton.

Both she and Bass revealed the idea came as COVID quarantine restrictions last March left them and their fellow academics scrambling for things to occupy their time.

“We could make face shields,” Bass explained. “So there were three main faculty, and I was one, Amy the other. The other had a student who had a 3D printer, and that student had been making shields already off a plan taken from the internet. The student printed the head band, and we did assembly in a kitchen. It quickly became apparent the location wasn’t going to accommodate demand.”

Along with deans of the respective schools, Drexel’s Board of Trustees caught on and offered $10,000 for the project. Bass said the dean of the engineering school helped secure some space at Drexel, with personnel restrictions, along with access to the university’s machine shop.

There, crafting the shields bit by bit with scissors and glue and a slow printer evolved into faster production, and with the help of an outside company that provided injection molding, fabrication jumped from a few in a day to 1,000 per week.

“I took on the logistics of the production and manufacturing aspects,” Throckmorton offered. “I went to a Home Depot off Route 70, close to where I live, and talked to the manager about building face shields for care facilities.

“The Lowe’s on Route 73 also helped out,” she added. “A manager contacted the company CEO and got immediate permission to contribute $1,000 for glue, specialized foam tape and cable ties. I kept going back for more, and discounts were applied each time.”

With all the pieces literally in place, an initial target of 6,000 shields was passed within a month of starting mass production, Throckmorton stated. The group then passed the 10,000 mark at the beginning of May.

With the milestone of one year since COVID arrived having passed, neither Bass nor Throckmorton will cop to having a “sob story” about how the pandemic has affected their lives.

“To fulfill such a critical need feels so great. We’re a bunch of academics, and to be able to roll up our sleeves and get things done is wonderful,” Bass noted.

“There were a lot of nights I went into the shop, and what would I be doing otherwise? We were told by the governor we had to stay inside. I could learn to knit, or cook, or I could learn how to use a Dremel power tool.”

Throckmorton had inspiration from her brother, a paramedic and firefighter in Norfolk, Virginia.

“It puts you in a vulnerable place, where you realize how (the virus) becomes personal,” she said. “The links of the supply chain were broken. We are academics, but what we do is a service mindset. Thanks to what we’ve accomplished, the supply chain has been repaired.”

Thanks to the generous financial donations from the above-cited sources, the shields are free to any organization that requests them.

Throckmorton related that providing shields to school districts is on the horizon, with students coming back en masse and the need for increased safety measures an immediate concern.

“We don’t plan to stop unless Drexel plans to kick us out,” Bass added.

For more information about the project, visit: https://faceshields.cci.drexel.edu/